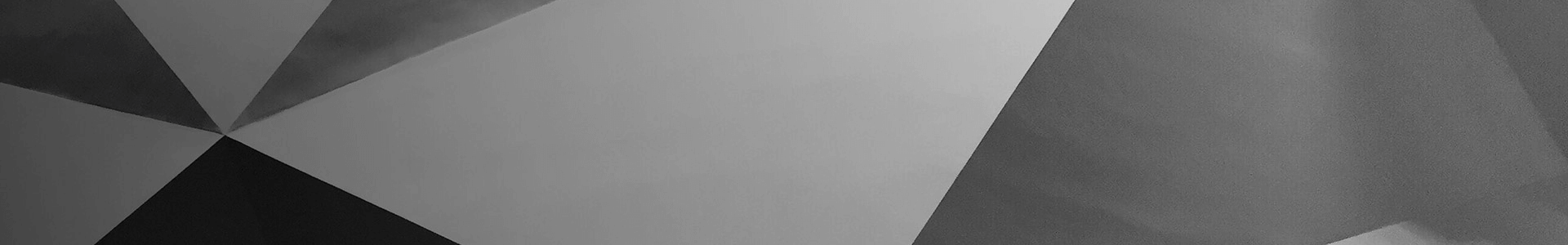

Hot DIP Galvanized Outdoor Bike Parking Floor Double-Sided Rack Stands

Basic Info

| Model NO. | PV-0043-01 |

| Material for Bicycle Parking Stand | Powder Coated Steel |

| Package Dimensions | 40cm X 34cm X 43cm |

| Years of Our Factory | 18 Years |

| Size | 107cm X 34cm X 24cm |

| Brand Name | Lingxi |

| Net Weight of Bicycle Parking Stand | Approx. 5.1kg |

| Use | Bicycle Parking Stand |

| Mount Type | Floor Mounted |

| Packaging for Bicycle Parking Stand | Iron Frame |

| Supply Ability | 30000 Piece/Pieces Per Month 5 Bike Rack Accep |

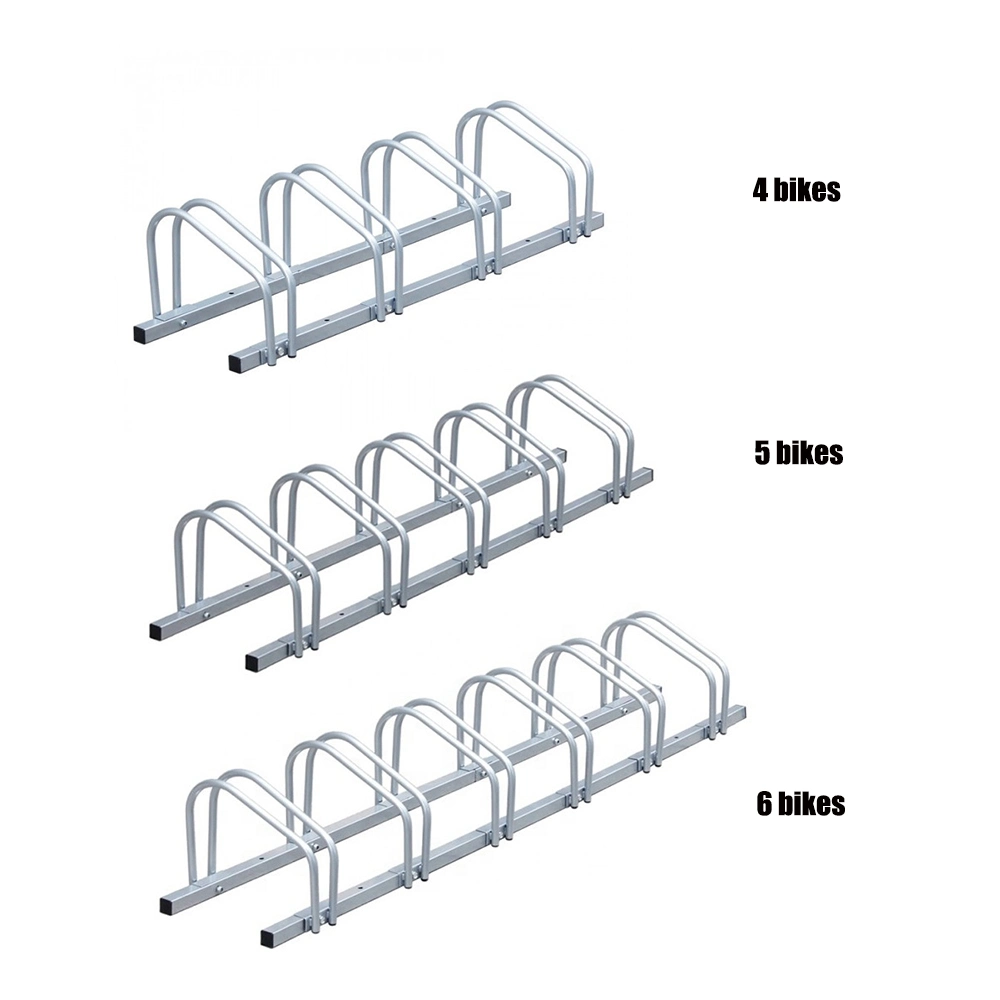

| Capacity for Bikes | Can Be Customized |

| Transport Package | Wooden Pallet |

| Specification | 107cm x 34cm x 24cm |

| Trademark | van |

| Origin | Suzhou |

| HS Code | 7326909000 |

| Production Capacity | 1000000 PCS / Month |

Product Description

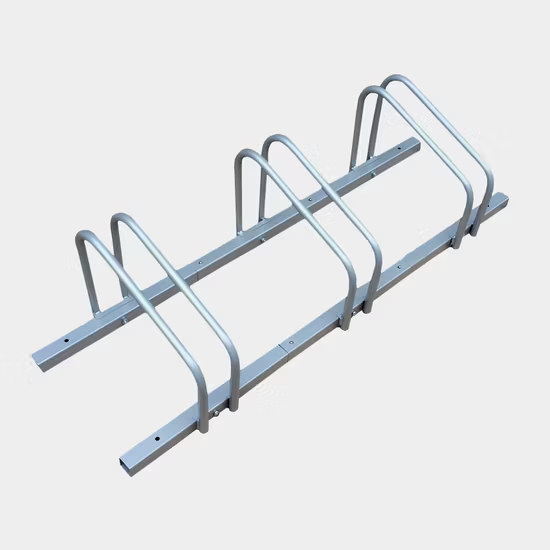

Main Features:

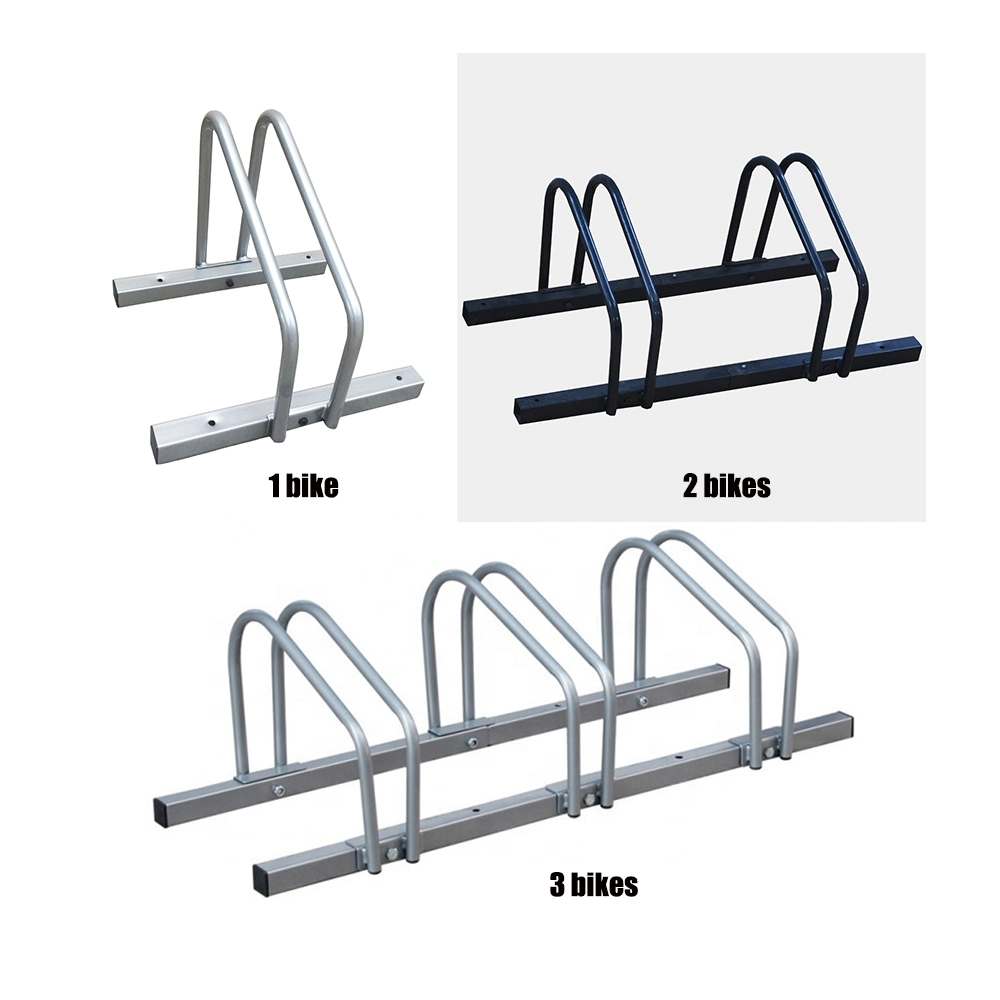

This 5 Bike Rack is floor mount. This type of Cycling Rack is extremely sturdy and durable. This type of 5 Bike Rack can beboth for indoors and outdoors.This pattern of Cycling Rack can be customized into 2 slot rack, 3 slot rack, 4 slot rack, 5 slotrack, 6 slot rack etc. This cycling rack is ISO 9001 certificated. Our factory accept customize for 5 Bike Rack.

The dimensions of Traditional Bike Rack is W890*D760*H693mm. The capacity of thisTraditional Bike Rack is 6 bikes. The finishof this Traditional Bike Rack is Powder coating. This Traditional Bike Rack is made by 1-5/8" OD frame with 14-gauge crossbarssecurely welded at top and bottom. The color of this Traditional Bike Rack can be Optional. Our Traditional Bike Rack arewaterproof, anti-rust, durable, weather resistant. The raw material for this Traditional Bike Rack is carbon steel. Our factoryaccept customize for Traditional Bike Rack

Main Features

1) The dimensions for this Traditional Bike Rack is W890*D760*H693mm2) The model number of this Traditional Bike Rack is PV-B04-63) The capacity for this Traditional Bike Rack is 5, 9, 10, 18 bikes.4) The sizes for this steel frame for the Traditional Bike Rack is 1-5/8" OD5) The load capacity for this Traditional Bike Rack is 100 kg

| Product | Hot DIP Galvanized Outdoor Bike Parking Floor Double-Sided Rack Stands |

| Material | Stainless/ Carbon Steel |

| Model No. | PV-0043-01 |

| Size | 100.5*32.6*26.6CM or customized. |

| Color | Sliver,Black,White or customized. |

| N.W/G.W | 4.57KG/5.03KG |

| Packing Details | 1Set/Bubble wrap/Carton |

| Capacity | 3 bikes |

| Surface Treatment | Galvanized/ Powder coated |

| Application | Outdoor bicycle parking storage |

| Sample Time | 7-12days |

Detailed Photos

Production Process

Tube Cutting

Laser cutting is a technology that uses a laser to cut materials, and is typically used for industrial manufacturing applications,

but is also starting to be used by schools, small businesses, and hobbyists. Laser cutting works by directing the output of a

high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct

the material or the laser beam generated.

Tube Bending

Tube bending is the umbrella term for metal forming processes used to permanently form pipes or tubing. One must

differentiate between form-bound and freeform-bending procedures, as well as between heat supported and cold forming

procedure

Welding

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing fusion,

which is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt

the base metal. In addition to melting the base metal, a filler material is typically added to the joint to form a pool of

molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration,

fillet, etc.), can be stronger than the base material (parent metal). Pressure may also be used in conjunction with heat,

or by itself, to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from

being contaminated or oxidized.

Smoothing the surface

To make surface of the metal products clean and nice.

Company Profile

Suzhou Pioneer Vehicle Company was founded in 2000 years,we have more than 15 years of experience in processing metalproducts.Our factory covers an area of more than 7000 square meters, we nearby the beautiful Lingyan mountain which locatedin Mudu town,Suzhou city.Our factory have all kinds of stamping equipment around 30 sets,Semi-automatic and full automaticspot welding machine 5 sets,Gear machine 2 sets,Sawing machine,CNC machine,CNC bending machine,Pipe bending machine,Arc machine etc,more than 20 units types of welding machines.There are various types of processing equipment more than 50 units.We have rich experience for Turning,Milling,Planing,Grinding,Drilling and Tapping,Punching strerching,Welding bend etc.We have integrity and pragmatic spirit,we regard product quality as thelife of enterprise,we offer good quality and efficient service to the new and old customer!

After Sales Service

| Quality Assure | ISO CE SGS TUV approved |

| 1 year warranty | |

| Rust-proof: 3-5 year for powder coated products and 10-15 years for galvanized products. | |

| Stable customer in the US, Europe and Australia. |

FAQ

1.Can you print our logo on the products?

- Yes,of couse.Just give us your logo image and tell us your requirement,you logo will be perfectly showed on it.

2.Can we make our own design on packaging?

- Sure,most of our clients are using their self-designed packaging.

3.If we can make some change to your products?

- Customization is welcomed!We are glad to assist you in making the products better and we will protect your design.

4.What's your lead time?

- Normally 7 working days for sample,30 working days for mass production.

FOR MORE PRODUCTS,PLEASE CLICK HERE!